|

LAMP WICKS & CHIMNEYS - CLICK HERE

WICKS TO FIT THE HEATERS LISTED BELOW - AND MORE!

Unique Specialty wicks

|

World's Largest Selection of Wicks! FLAME SPREADER LAMPS AND HEATERS Robert E. Dietz submitted the first patent for a flat wick lantern burning the new "coal oil" in 1857. Production of the lamps begin in 1859. Dietz was not just an inventor - he was one of the first environmentalists. Prior to his new flat wick lamps, lamps burned whale oil. Whale oil lamps were smelly and smoked a lot, and the light output was poor. Dietz could also see there was a infinite supply of coal, a rather finite supply of whale oil, and getting the whale oil was rather rough on the whales. Within a few years, the whaling industry took a hit and more whales survived, while at the same time home lighting was vastly improved. But flat wick lamps and lanterns have a problem: turn the wick up higher for more light, and they admit insufficient oxygen for proper combustion and begin smoking. The flame spreader was patented on Jan. 15, 1884 for use in circular, center-draft worsted woven wick lamps. This development introduced oxygen to both the inside and outside of the wick, resulting in considerably greater efficiency when a properly designed flame spreader was inserted into the center draft tube. Quite the opposite from a flat wick, the flame spreader type lamps mandated that the heat output be maintained at a high rate so the flame spreader itself was heated sufficiently to burn all the various liberated hydrocarbon products (coal oil), and turning them down caused in incomplete combustion process. All this was before the discovery of kerosene as a petroleum byproduct. The oil companies did their best to imitate coal oil with a product they called kerosene so they could have a market share in an already established market. Flame spreader design heater and lamp wicks are made of cotton. Modern catalytic converter heaters operate at a higher temperature than flame spreader heaters and also utilize a wick with the top section being fiberglass fibers (to contend with the higher heat), and thus can burn lesser quality kerosene, some even red dye kerosene, with a clean, odor free burn. Absolutely clear kerosene must be burned in flame spreader design lamps and heaters to have them produce a clean, odor free burn. HOW LONG WILL COTTON WICKS LAST IN USE? Fiberglass wicks can be burned dry. The disadvantage of cotton wicks is that the cotton itself can burn. With care, a cotton heater wick can last one heating season. But if the heater is allowed to run out of fuel then the wick itself will burn down 1/4". If the heater runs out of fuel 3 times the wick is shortened 3/4" and the wick life is consumed - a new wick is required. So how long a wick lasts depends upon the user. HISTORY OF FLAME SPREADER HEATERS AND LAMPS Beginning in 1884, circular wick lamps with flame spreaders were produced in great quantities in the area around Meriden, CT, by Bradley & Hubbard, Plume & Atwood, Miller and many other companies, most of the early models sold under the Rochester name and made by Miller. By 1886, Rochester lamps were in production of "store lamps" using a 2 9/16" wick, soon followed by almost all other lamp companies. In 1888, the Perfection company began producing center draft, flame spreader lamps at their Cleveland Foundry.

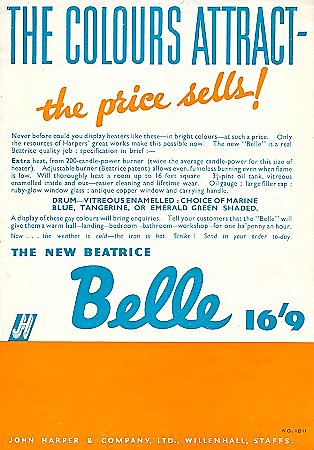

In 1894, Perfection basically scaled up their lamps to use a 2 9/16" diameter wick, put the fount in a housing, and began selling portable space heaters using their new "500" wick, although the name "Perfection" was not used until 1901. The difference between the heaters sold by Perfection and the large lamp companies was in the wick carrier: they all used essentially the same 2 9/16" diameter wick, but the Perfection wick system was sold with the wick carrier while other heaters used the same wick carrier as in their lamps. It was easier to change the wick in a Perfection heater than in a lamp-based heater, Perfection heaters were inexpensive, and that pretty much ended production of lamp-based heaters. Work on flame spreader lamps and heaters was also taking place in Europe. In France, a beautiful series of Kosmos lamps (Gaudard) were designed in the late 1880's; the equipment to make them using a modified water wheel was manufactured in Brooklyn, and is still in use today in the South of France. In England, Valor and Beatrice were producing some very fine parlor heaters, most using a variation of the 1 1/2" center-draft wick used in B&H and P&A lamps, although Valor did produce a virtual clone of the Perfection 500 heater. Photos of some of those Valor and Beatrice heaters from my collection are shown below. With a few exceptions, production of flame spreader heaters ended in about 1981 with the introduction of catalytic converter heaters made in Japan. The exceptions were the Moonlighter and Omni 15 heaters made by Toyotomi, the Corona SS-DK and SS-DX, the KOGY 200A (all being essentially shrunken Perfection heaters with an updated cabinet design), and POD heaters. Production on all but the POD ended by the early 1990's. POD may still be making heaters, but it is extremely difficult to determine as they try very hard to have no visible marketing plan. ======= What doomed flame spreader designs? The tip-over safety switch. "Use only listed heaters. Only heaters that have been tested and listed in accordance with Underwriters' Laboratories (UL) Standard 647 [dated July, 1983] should be purchased and used. This listing should be shown on the name plate of the heater. "Most portable kerosene heaters are similar in

design. They include a wick so kerosene can be drawn from the tank to

the combustion area, a device for igniting the wick, an automatic

tip-over device designed to extinguish the wick if the unit is

kicked or turned over and a fuel tank."

Without UL Approval, retail stores could not obtain insurance for the sales of kerosene heaters to cover any potential problems and manufacturers of heaters could not get product liability insurance. Perfection and Valor tried to develop safety tip-over switches but they were cumbersome and difficult to use. It is very difficult to ascertain the precise date that Perfection, Valor and Aladdin flame spreader heaters went out of production, but 1984 appears likely the last year of production. POD in Sweden continued to produce flame spreader heaters but without UL Approval: distribution of POD heaters was severely restricted as a result and they are difficult to find.

To reiterate, flame spreader lamps and heaters should be burned at a very high heat setting so that the flame spreader is sufficiently heated to complete the combustion process, but they can be turned down to produce less heat and most of them still will burn quite cleanly. Catalytic burner heaters must be burned at 90% or more of rated capacity to burn cleanly.

`

FLAME_SPREADER_DIAMETERS (A selected few)

========================= Beatrice Wick Sleeves Are not Interchangeable

`

Some of the older center draft wicks are becoming difficult to find. Then one must be a little creative. For example, for the past several years the Valor Valmin wick was in short supply. My previous models were a very rigid wick, with what looked like an inner core of thick cardboard, to which a metal "ladder" had been attached to engage the wick raising ratchet gear. There was no way that wick could be home made or modified from anything else. The last small batch of Valmin wicks I received, however, were made just like the originals over a hundred years ago - still a stiff wick, but inside a steel sleeve.

Now I had something with which to work. I ground off the rivet heads, removed the rivets, and then removed the stiff inner brand new wick. Then I drilled a 1/8" hole in the steel sleeve close to the hole already present for the rivet. The next step was to insert a 1 1/2" #2T wick in the sleeve, and sew it in place through the holes on each side of the steel sleeve, with the same amount of wick projecting as shown on the original wick in the photo above right. It works perfectly! Previously, many Valor heaters using the Valmin wick sat unused, or were discarded, because new wicks with the ladder arrangement (as shown above left) were simply not available. But Beatrice 4012 center draft wicks will always be with us, they are precisely the same diameter as the Valmin wick, and the steel sleeve will last virtually forever. My Valor 420 (shown) below has been in use 16 hours a day for weeks heating my office, burning perfectly, cleanly, with no aroma, with a #2L wick sewn into the steel Valmin wick sleeve. This little trick could keep many fine Valor heaters in operation for another hundred years! (The W44 wick sleeve will fit many old Brit ''Parlour Stoves" but not the Beatrice models shown above.)

`

`

This page is a work in progress and will be completed as I find the time. I can only photograph items which I own, and I'm trying not to overload this page with too many photos of different heaters and lamps while still illustrating the extreme similarity in the basic design concepts.

Lamp Collector’s Resource

Library: Old Lamp Catalogs on 3 CD's in

SEARCHABLE Adobe - NEW!!!

Click Here

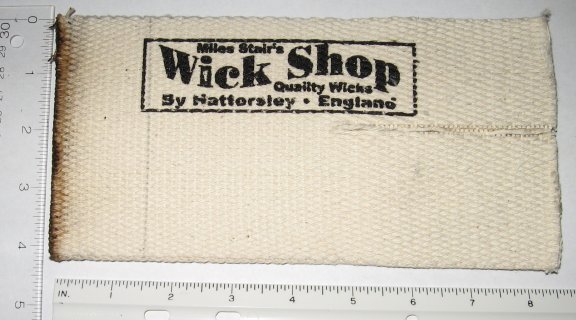

Lamp Wicks BY THE ROLL! - SAVE $$$

Lamp Wicks:

Center Draft Wicks

- many

available only from this Wick Shop.

#0C,

#0S,

#0L,

#1B,

#1M,

#1R,

#2M,

#2L,

#2R,

#2 P&A,

#2B,

#3L.

Aladdin Lamp Wicks,

chimneys etc

HI SEAS 100C MARINE

Lamp Chimneys:

Center Draft Lamp

chimneys in borosilicate glass

from Junior "Tiny" to Mammoth lamps.

#0M,

Rayo

Jr.,

2

1/2",

2 5/8",

2

15/16",

3 1/8",

4",

4

1/2"

Standard glass lamp chimneys

& Kosmos chimneys

Fabulous "Sans Rival"

borosilicate chimney for 14''' Kosmos lamps

Student Lamp Sans Rival Chimney with

1 7/8" fitter!!!

Information on lamps:

Aladdin Lamp Wicks & Chimneys,

Aladdin - Exploded burner views

Lamp Repair & projects

Center Draft Kerosene Lamps

Early American Metal Font & Specialty Lamps

Flame Spreaders and

"Smoke

Consumers"

from Alex

Marrack

Articles by Alex Marrack:

Registered Design Numbers For British Lamps

GERMAN PATENT LETTER CLUES - DRPs AND DRGMs, 1877 to 1945

Site Index for all things Perfection

Links to web sites for parts,

information and restoration.

Site Index for all things Perfection

Kindler Wicking For Oil Stoves & Ranges

Kerosene Heaters

Alphabetical list of most kerosene heaters and the proper wick,

& cart checkout.

List by wick number and the heaters that fit them. (A

helpful guide for buying on eBay)

Measurements needed if you have an unlisted heater.

Care and Maintenance of Kerosene Heater Wicks

Installing Kerosene Heater Wicks - generic for unpinned

wicks

Owner's_Manuals & information for many kerosene heaters

Kerosene

Heaters - General types, how they work, recommendations

for some good ones - and those I would avoid.

Economic Benefits of

Kerosene Heaters

Troubleshooting kerosene heater common problems

Breaking

In New Kerosene Appliances

Burning

Kerosene Heaters at Night

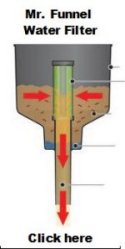

WATER IN KEROSENE causing "dwindling" and poor

performance.

Flame Spreader Heaters

and Lamps -

Kerosene Heater Carts

-

Kerosene tank cradles

(photo)

Building a Cradle

KEROSENE

HEATERS MADE IN THE NETHERLANDS

Beatrice Boiling Stoves & Mini kerosene heaters

you can make

Sad Iron stoves; Wicks &

Installation instructions

Wicking For Oil

Burning "WICKLESS" Stoves & Ranges Kerosene Stoves, Lanterns and Ovens

Recommendations on different models

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||